Production Process

Production Process

Raw material

01

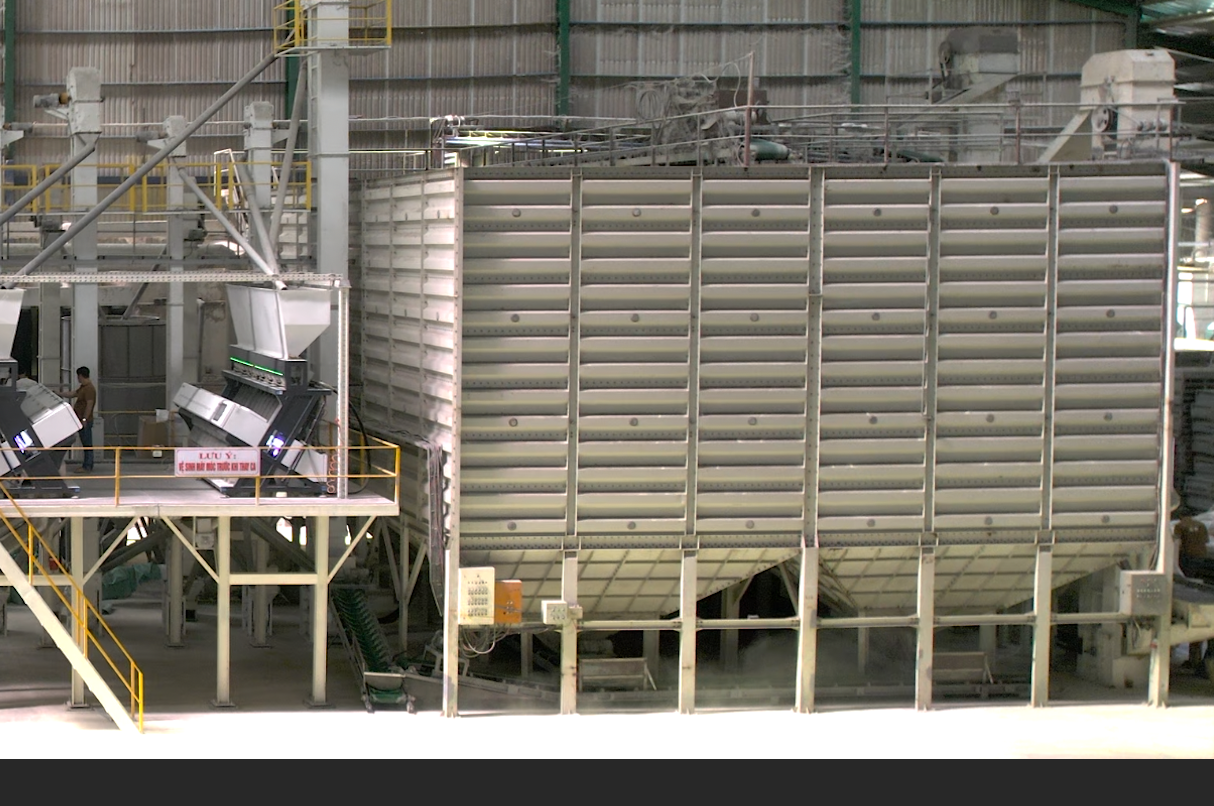

Rice Dryer

02

Paddy Silos

03

Rice Huller

04

Brown Rice Silos

05

Whitening & Polishing Machine

06

Grain Sorter

07

Finished Product

08

Packaging

Step 01

Step 02

Step 03

Step 04

Step 05

Step 06

Step 07

Step 08

Step 01

Rice DryerFresh rice after harvesting is transported to the factory by boat or truck. Here, the raw materials are checked for quality and must meet the input standards. Fresh rice with high moisture content is put into the rice drying system to reduce moisture before milling. Achieving the correct moisture content will help the milling process to proceed smoothly and ensure the quality of the rice grain.

Step 02

Paddy SilosDried rice that meets the standard moisture content will be placed in an enclosed paddy silo to await milling.

Step 03

Rice HullerDried rice is put into a rice mill to remove the husk and become brown rice.

Step 04

Brown Rice SilosThe brown rice is then moved to a closed rice storage tank to await whitening and polishing.

Step 05

Whitening & Polishing MachineBrown rice after husking is put into a whitener to remove the bran layer. The bran will be put into bags at this step, and the whitened rice will be put into a polishing machine to create a glossy finish for the rice grains.

Step 06

Grain SorterAfter being polished, the rice is put into a grain sorter to screen out mixed grains, broken grains, and unfilled grains. At the same time, the rice will be passed through a screening machine to remove impurities such as sand and dust.

Step 07

Finished ProductAfter completing the above steps, the finished product will be carefully evaluated by reputable inspection representatives selected by the customer.

Step 08

PackagingFinished products then will be packed in requested packaging by the customer. Then, the products will be transported by boat or road.